from raw materials to premade cables

To ensure we always achieve the highest quality, we impose rigorous high standards on our production processes. We are convinced that we can only achieve these standards at our production facility in Germany.

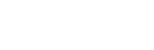

Top-quality raw materials, state-of-the-art production systems, highly qualified staff and a modern production planning and control (PPC) system all ensure our premade cables achieve consistently high quality standards. We have maximized the efficiency of our fibre-optic and copper cable production, by ensuring all processes undergo continuous monitoring and improvement.

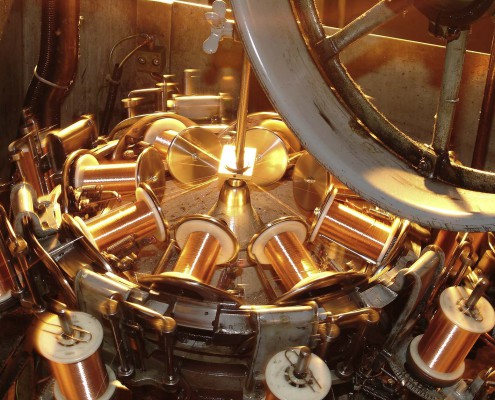

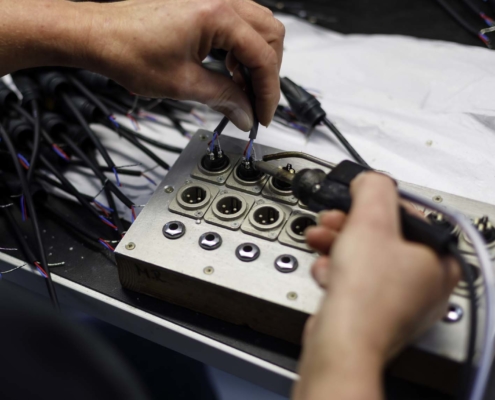

Cables and connectors are assembled into individual cables in a series of precisely coordinated steps. Depending on the cable type, various connection technologies are used.

All our cables undergo extensive functional testing before they leave our premises. The premade products are then automatically packaged in fold-over cardboard packs or blister packs by our modern production lines.

This ensures our customers receive a high-quality product with a long service life – which is good for their budget and good for the environment and our resources too, by minimizing the carbon footprint of our products. Proactive environmental protection is paramount for us, both in our production processes and in our choice of raw materials.